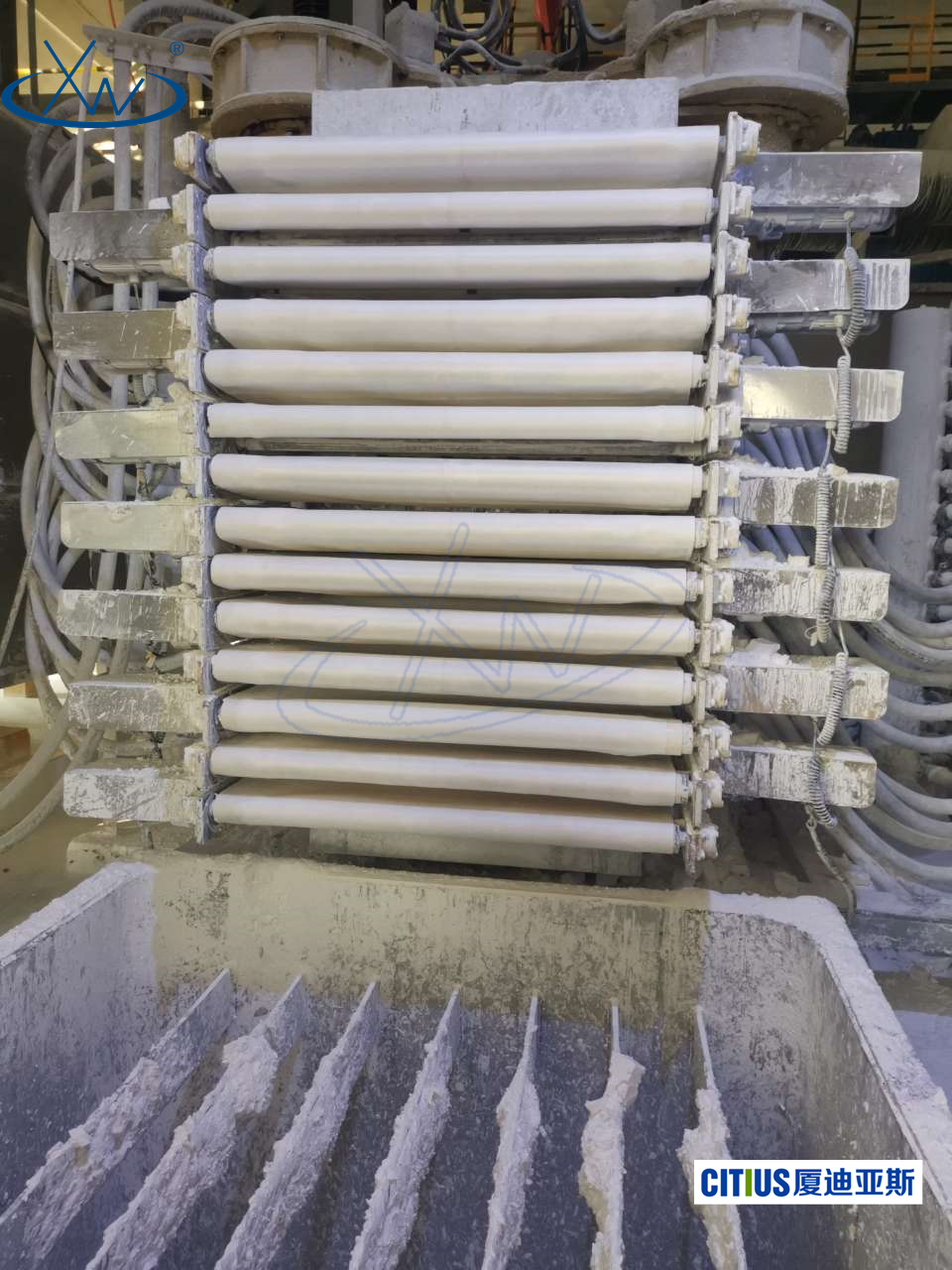

Vertical filter press filter cloth with ultra-high retention precision for chemical filtration of alumina.

Share to

Detailed Description

1. Process Requirements for Alumina Filtration

In the alumina production process, key processes such as red mud separation and seed washing have extremely high requirements for filtration accuracy and filter cloth performance. The alumina slurry has fine particles and strong fluidity; if the filtration accuracy is insufficient, it can easily lead to solid losses or turbid filtrate, affecting product quality. Therefore, vertical filter presses have become important solid-liquid separation equipment in the alumina industry, and high-performance filter cloths are one of their core components.

2. Key Performance of Vertical Filter Press Filter Cloths

The filter cloths provided by Xiamen Citius for vertical filter presses are specially developed for the alumina filtration process and have the following characteristics:

- Ultra-high retention accuracy: The filter cloth uses precision weaving technology, with a uniform pore size distribution, effectively retaining fine particles, ensuring the clarity of the filtrate, and improving product purity.

- High-strength wear-resistant material: Made from high-strength polyamide (PA) or polypropylene (PP) filter cloth, resistant to high pressure and wear, suitable for long-term high-load operation.

- Excellent chemical corrosion resistance: Resistant to strong alkaline environments, suitable for high-temperature strong alkaline process conditions in Bayer alumina production, ensuring stable filtration performance.

- Good filter cake release properties: Smooth surface treatment reduces filter cake adhesion, improves discharge efficiency, reduces downtime, and increases equipment operation rate.

- Low clogging and easy to clean: Unique weaving structure reduces particle embedding, improves regeneration performance, extends service life, and reduces replacement frequency.

3. Application Advantages

- Improved filtration efficiency: Optimizing the filter cloth structure design increases the filtration flux per unit time, enhancing overall production efficiency.

- Reduced production costs: Reduces solid losses, increases alumina recovery rate, while extending filter cloth life and lowering operating costs.

- Adaptability to different process requirements: Customized filter cloth solutions can be provided according to different filtration stages in the alumina production process, ensuring optimal filtration results.

4. Conclusion

Alumina production has strict requirements for filtration accuracy and durability, and the choice of vertical filter press filter cloth directly affects separation efficiency and production efficiency. Xiamen Citius, with advanced filter cloth technology and rich industry experience, provides filter cloth products with high retention accuracy, strong alkali resistance, and high pressure resistance, helping the alumina industry optimize filtration processes and enhance production efficiency. For customized filter cloth solutions, please feel free to contact us.

- Vertical filter press filter cloth 2015 applied in chemical alumina filtration

Filter machine type: Vertical filter press

Application industry: Chemical

Material description: Alumina

Filter cloth model used: 2015 - Xiamen Citius model 2015 filter machine filter cloth product parameters

Belt material: PP imported short fiber

Applicable model: Vertical filter press

Main features: Ultra-high retention accuracy

Applicable industry: Chemical industry